HITECO & ABB COLLABORATION

Simple installation, use and programming as well as flexibility and efficiency are the factors that are increasingly driving the use of robots in the engineering

Simple installation, use and programming as well as flexibility and efficiency are the factors that are increasingly driving the use of robots in the engineering

150B in operation increasing customer’s production by 30%. This spindle is a beast making 29 NM constant torque and a huge HSK 80E taper. Perfect

Economy Spindle Repair Economy spindle repair service is a new level of service in addition to our standard and expedited repair services. The economy service

Spindle Showdown! Product Comparison: 60C to HSD AT/MT 1073 This Spindle Showdown will compare our High Speed 60C Spindle to the HSD AT/MT 1073. The

Product Highlight – HSK 63F Gripper This product highlight is on our HSK 63F Gripper. (Video Below) The tool holding clamp group is a.k.a. a gripper. The gripper is

Latest Repair GMN Spindle New repairs are rolling on this new year and we want to provide you a behind the scene look at one of our

Spindle Comparison: 70C vs IMT ECO80 Model This post is a spindle comparison of two HSK 25E spindles. Both are high precision and high speed: 30,000

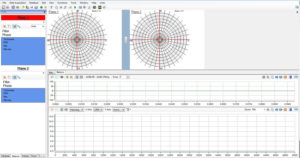

All spindles are dynamically balanced and have a vibration analysis performed. If any critical speeds are detected, we’ll inform you of the speed zones to

HS Spindles is a veteran owned manufacturer and repair shop for high speed spindles. We have an online store to support CNC tooling needs.

Copyright © 2024 HS Spindles All Rights Reserved